Process Intensification

Inline buffer preparation enhances production

Biopharmaceutical production relies on buffers, and ensuring that the right buffer solution is available at the right place, at the right time, and in the right amount on the production line is a considerable challenge. Meanwhile, in the face of increased production capacity and expanded demand, how to complete the transformation work as quickly and economically as possible is also a common thorny issue. Depending on existing infrastructure, batch sizes and facility utilization, there are different solutions to improve the productivity and efficiency of downstream operations. The balance between effectiveness and productivity will require new technologies to maintain. The previous capital-heavy strategy of rapid single-point breakthrough cannot adapt well to future competition. Flexible and efficient platforms will be more favored.

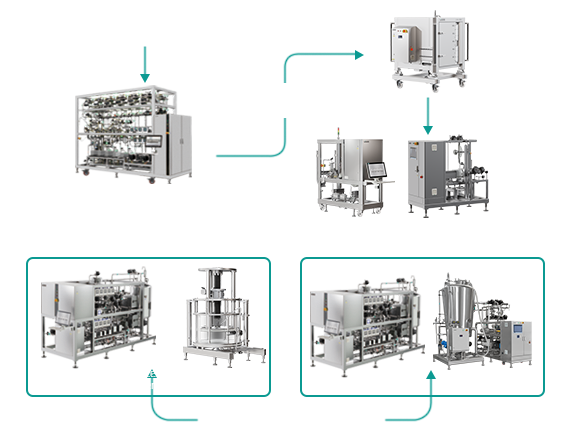

In recent years, Lisure has accelerated the promotion of overall solutions for online liquid preparation and downstream processes to strengthen downstream production processes and improve economic benefits. Lisurei currently has two buffer configurations: IDPC and ICPC, which correspond to inline dilution process chromatography system and inline conditioning process chromatography system respectively. Buffers are prepared by diluting single-component, high-concentration salt, acid, and base stock solutions with WFI and using dynamic control with different feedback control modes to ensure accuracy.

Save buffer prep time and use amount

Reduce investment costs

Flexible and precise configuration of various buffers

Efficient continuous automatic buffer preparation

Accurate preparatoin of multiple buffers

Flexible and integrated into chromatography and ultrafiltration equipment

Hybrid mode applies different pipelines

Multi-system platform support + SCADA/MES support

CIP chromatography system

Read More

Buffer preparation chromatography system

Read More

Series-parallel chromatography

Read More

SPTFF

Read More