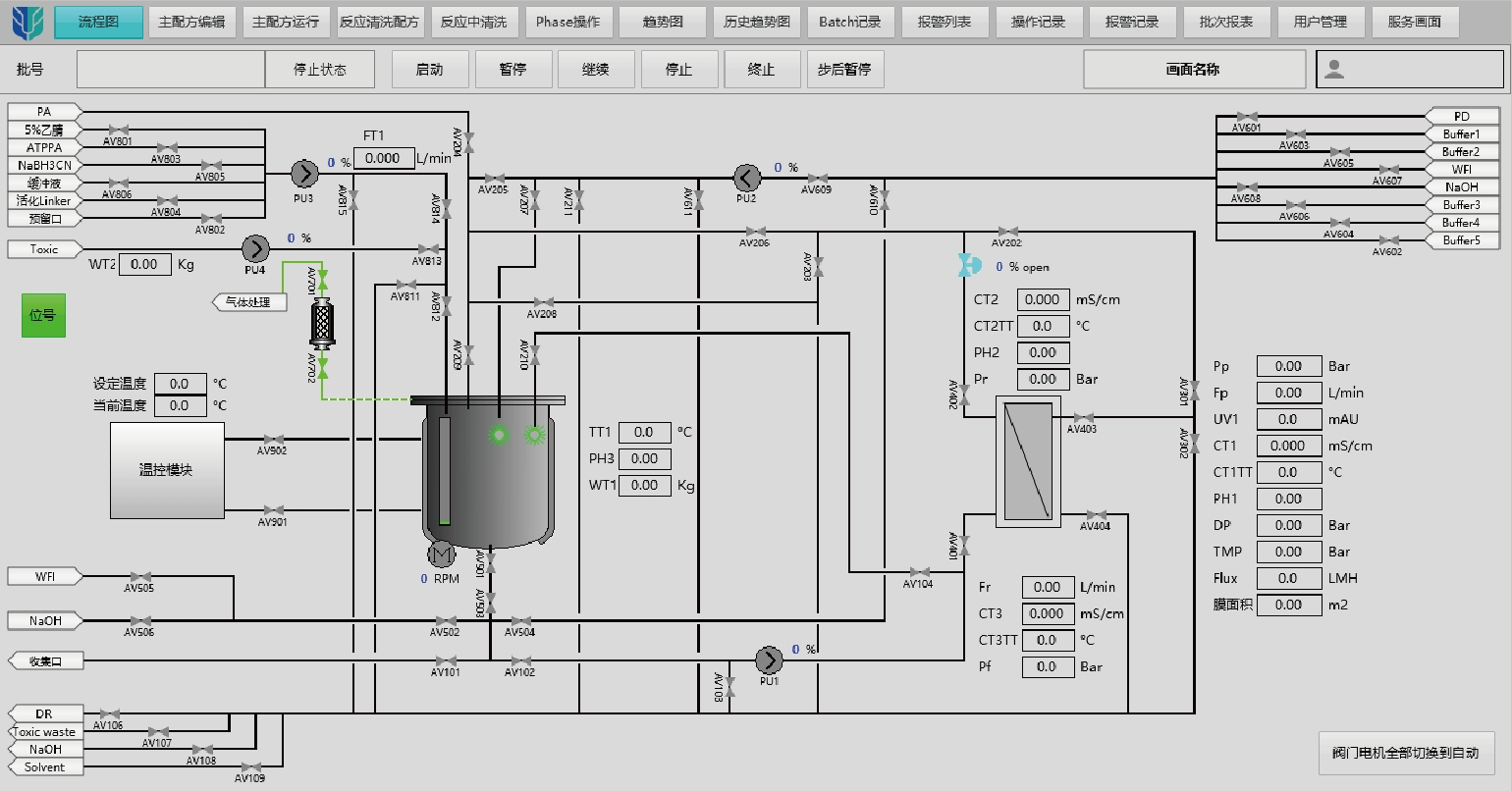

Automated Ultrafiltration System

Fully automated ultrafiltration system is specially designed for downstream separation and purification of biopharmaceuticals. The system can be divided into concentrated liquid exchange or clarification microfiltration according to different processes. It can be divided into membrane cassettes or hollow fibers according to different types of consumables. The highly customized system perfectly fits the process requirements and can provide products and services that comply with GMP. The product line covers everything from lab-scale, pilot-scale to process production. It is suitable for biopharmaceutical customers of different scale and stages.

Flexible Type

Multiple-control Modes

Multi-platform Software

Online Integrity Testing

Water Flux Test

Customized Design

The filtration type can be selected flexibly according to different processes, which can adapt to the different kind of hollow fiber cartridge and flat membrane cassette, to realize ultrafiltration, concentration, buffer exchange or clarification microfiltration process.

The control strategy includes various control modes such as constant TMP, constant Fr, constant △P and fixed pump speed, covering the need for most ultrafiltration processes. Other special control strategy can be customized.

All control platforms meet the requirements of FDA 21 CFR Part 11 electronic signature, electronic record and audit trail requirements.

The system includes an inline integrity test module, which can complete the integrity test without disassembling the membrane cassettes/cartridge, based on brands, models, and membrane areas. Test result can be saved in the batch report.

The system can perform inline water flux test function, and save the result in the batch report.

The system can be fully customized according to the plant layout and the process train to meet the customer’s need.

| Membrane Area |

| 0.1-0.5㎡ |

| 0.5-3㎡ |

| 0.5-5㎡ |

| 5-20㎡ |

| 20-40㎡ |

| 40-60㎡ |

| up to 300㎡ |

Delta V

Labwindows

WinCC

Ultrafiltration software can be based on different platforms, such as DCS (Delta V or PCS 7) or PLC control (WinCC or Lab Windows).