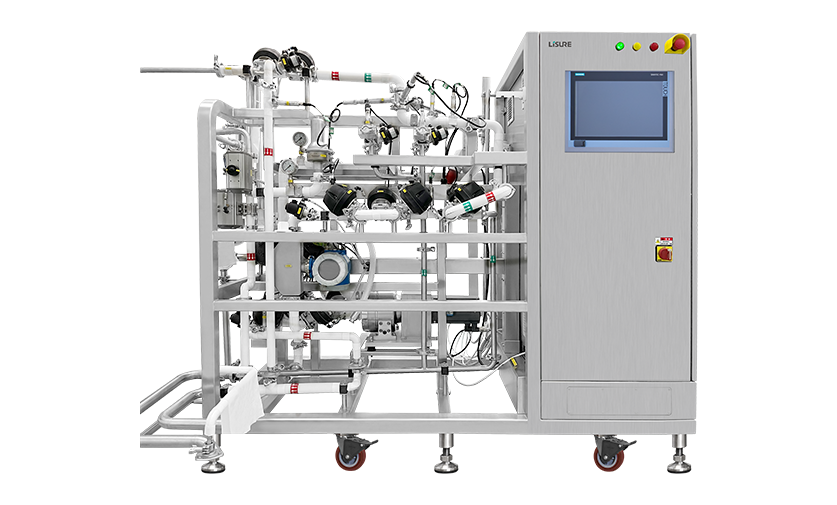

Virus Removal Filtration System

The VFS Virus Filtration System is a stainless steel automatic filtration system used in downstream production areas for virus removal from the final product.

Low Shear Force

Flux Maximum

Reasonable Structure

High Efficiency

The system is designed to provide robust process control during this critical downstream step.

Using standard Filter or Housing, the maximum operating flow rate of the system can reach 15000L/Hr.

The system is designed to have a fully automated process through recipe controlled steps including system start-up, ΔP values of product and filter, filtrate buffer tracking.

All data is stored in a batch reporting system, significantly reducing disqualification and labor work.

Configurable recipe control stages that automate pre-use system equilibration, product filtration and buffer flushing.

To keep process parameters within limits, the process selects control functions such as flow rate, differential pressure and inlet pressure.

Flexible configuration, compatible with all commonly used virus filters.

Human-machine interface (HMI) commands to record key process parameters.

The system has automatic CIP function, which reduces the manual operation required for cleaning.